Thermal Shock Testing

Thermal shock testing is conducted to determine the products ability to function either in it’s intended use, or in extreme environments.

These tests are performed to determine the products ability to survive constant or fast rate temperature cycling. We conduct thermal shock testing in New Zealand for a range of customers and industries.

Why thermal shock testing?

Thermal shock testing is a great tool for determining the resilience of electronic, electromechanical, plastic, and mechanical products that will be deployed in the medical, consumer, aerospace, defence, or automotive industries.

Exposing your product to environmental stresses reduces the risk of field failures brought about by changes in climate. In particular, electronic products suffer degradation through exposure to both temperature change and extremes. Plastics in particular expand and contract and this can lead to stress fracturing around screw bosses.

Our Espec Thermal Shock Chamber

Our Espec TSA-102EL-A is an air-cooled damper-style machine with a 102 litre capacity. Inside dimensions are 650x460x370mm and a single 50mm cable port is available.

The chamber has three zones - cold, hot and ambient air steps can be programmed.

Cold zone temperature range is -65 to 0ºC, hot zone +50 to 200ºC and the ramp rate is set by these extents and your profile. Ramp rates exceed 15ºC per minute typically.

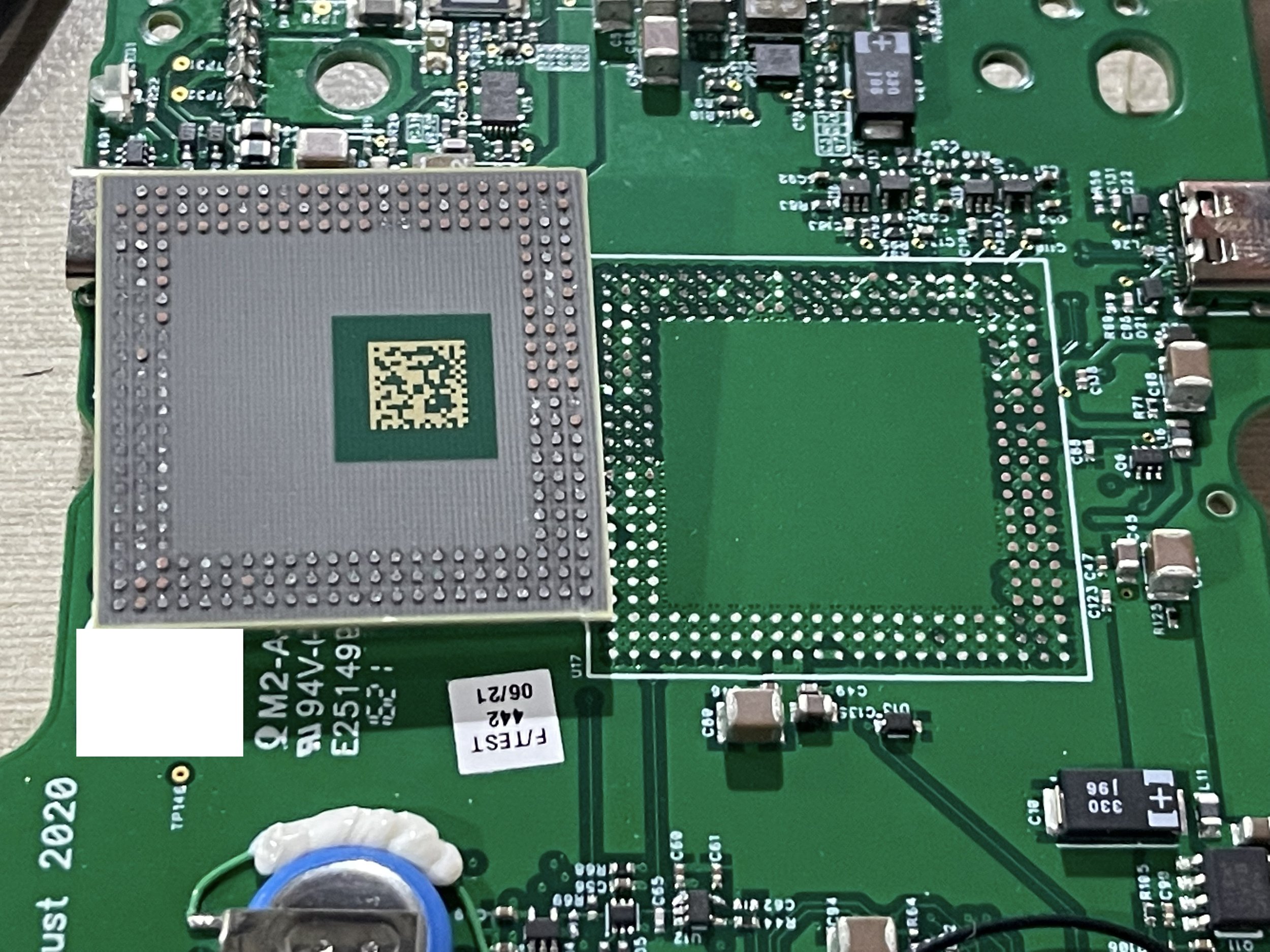

Soldering Issues

Conducting many thermal shocks on PCB assemblies is a great way to determine the effectiveness of the soldering process. In some cases poorly soldered components can fracture off a board without any additional stress (impacts).

BGAs and LGAs are susceptible to board flex, which is another stress caused by expansion and contraction of the underlying materials. The mounting points of the PCB hold rigid and the unmounted flex - typically complex components are placed away from mounting points due to PCB layout considerations.

An effective way to guard against flex is to use a thicker PCB. FR4 is not an expensive material but can add a lot of rigidity to the design.

Delaminating Layers

Complex parts including touch screens and solar panels can delaminate when exposed to multiple stress cycles. This is particularly true if contaminants have somehow formed in the manufacturing process between layers.

Any speck of dust trapped in one of the many layers of the stack up will cause air to be trapped too. This air will expand and contract causing a loss of adhesion in the product which will eventually lead to complete delamination in many cases.

Some of the worst offenders are polarising filters on touch screens, which results in real annoyance at the customer site because the viewing angle is severely limited.

Stress Cracking

Plastics can suffer from stress cracking or where parts are restrained in thermally divergent ways. Potted and overmolded parts are at particular risk if glass transition temperatures aren’t matched.

Another common place where plastics crack during thermal shock is screw bosses. These are often moulded into the plastic, and the different rates of expansion can cause the boss to crack loose during operation.

Thermal shock testing standards

Our machines can be used to perform the standard tests:

IEC-60068-2-14

MIL-STD-810

MIL-STD-311

MIL-STD-883

MIL-STD-202

DEF-STAN-00-35

JEDEC

ISTA & ASTM package conditioning

Internal development standards

Accelerated Life tests