You make it - we break it.

We love reliability, we're passionate about testing - and seeing how that helps companies increase profitability, market share and brand awareness. We’re HALT & HASS New Zealand: You make it - we break it.

Whether you're looking to improve your product using Highly Accelerated Life Testing (HALT), quantify product reliability using Accelerated Life Testing (ALT), demonstrate conformance with environmental testing or weathering, we can help.

We conduct Vibration, Shock, Thermal Shock, Temperature & Humidity, UV+Solar, Corrosion, Drop, Impact, Compression and Packaging testing from our lab in Canterbury, New Zealand.

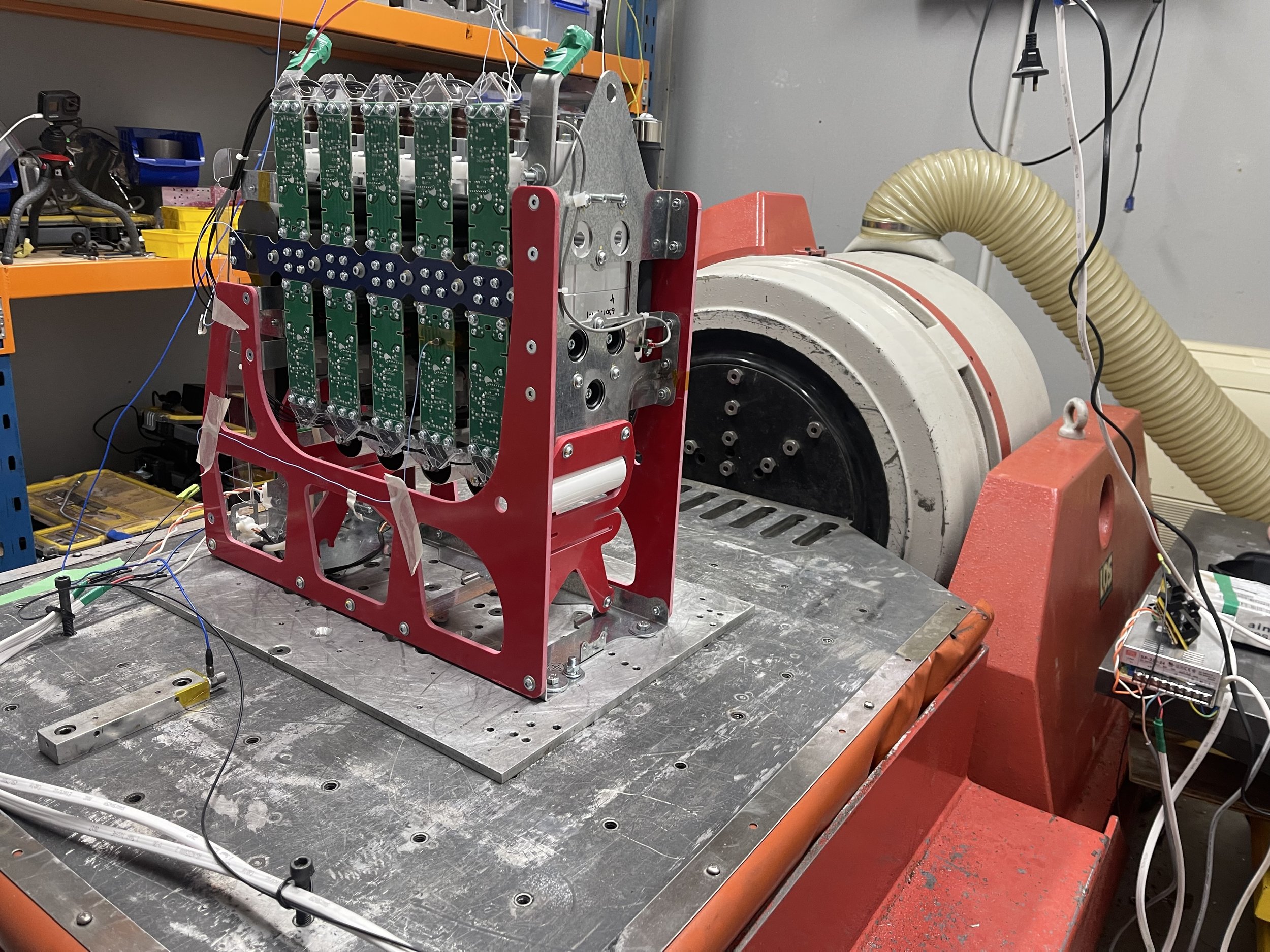

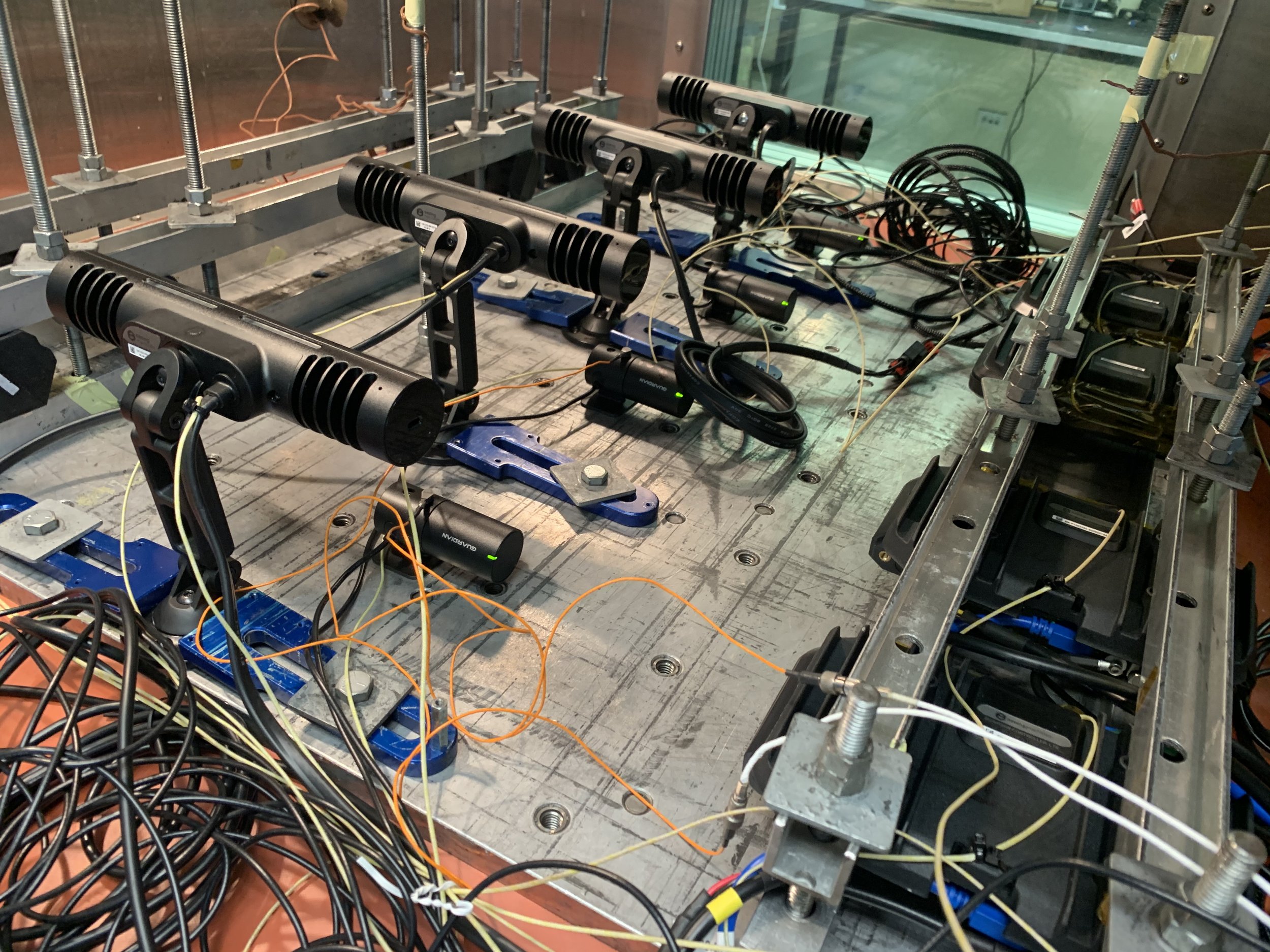

Vibration & Shock Testing

Our vibration shaker system includes support for sine, random, sine-on-random, random-on-random, classical shock, SRS shock, long waveform shock, time replay, multi-spot sine, and non-gaussian (kurtosis) random.

Highly Accelerated Life Testing :: HALT

HALT is an effective tool used during product development to stimulate design weaknesses into failure modes, where they can be diagnosed, and corrected before the product is introduced to mass manufacturing.

Thermal Shock Testing

Thermal shock testing is conducted to determine the products ability to function either in its intended use, or in extreme environments. These tests are performed to determine the products ability to survive constant or fast rate temperature cycling.

Package Testing :: ISTA ++

At our lab in Canterbury, NZ we operate Electrodynamic Shakers capable of performing transport vibration, package drop testers for dropping samples from 5-500kg and from 2 meters or below, and a compression tester for performing warehouse and truck stacking tests.

Corrosion Testing :: Salt Spray + Cyclic

Salt spray / corrosion testing is conducted to determine the products resistance to corrosion, often it is conducted at the product level to provide quick feedback to the development team on coatings, enclosures and connectors.

UV Testing :: QUV + Xenon-Arc

We seek shelter as one of the three requirements for basic life. Your products aren’t so lucky. They’ll endure years of abuse from the sun, temperature, humidity, moisture and corrosion.

Environmental Testing :: Temperature & Humidity

Temperature and humidity testing is conducted to determine the products ability to function either in its intended use, or in extreme environments.

Product Drop Testing

Our testers are designed to drop test products up to 1kg in weight from a repeatable height in varying orientations, ensuring that the testing you conduct provides solid data to gauge product weakness.

Tumble Testing

Tumble testing exposes your product to repetitive random free-fall drops in a controlled repeatable manner. These tests are performed to determine the products ability to survive the many bumps and scrapes it will experience in its life with an end-user.

Highly Accelerated Stress Screening :: HASS

Our experts are available to help you plan, setup, and run Highly Accelerated Stress Screening on your products. We understand that HASS is typically a big step for an organization and adapt our HASS plans to suit both the newcomer and experienced HASS user.

Reliability Demonstration Testing

Reliability Demonstration testing (RDT) is an efficient way to test whether the product will attain a specified reliability for a given life. This life is typically the products required useful life, it’s MTBF, or even warranty length.

Reliability Test Planning

Before jumping in at the deep end it pays to take an holistic view of your product life-cycle. What exactly are your goals for this product, architecture or system?

Looking for Test Equipment

Take a look over here.

Subscribe to our newsletter.

Sign up with your email address to receive news and updates.